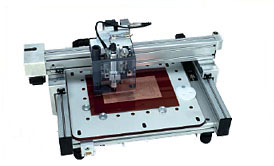

CNC Machines

CCD / 2

|

The Bungard CCD/2 is a high quality Computer Controlled Drilling machine with manual tool change. It allows direct processing of Excellon/Sieb&Meyer drill data or HP/GL data for PCB production (drilling, milling, isolation routing) and milling/routing of plastics, aluminium or other metal panels.

Compared to the CCD/MTC, it has 1/2 of the working area and a built-in control unit.

|

|

| Extend of Delivery |

- Mechanics unit

- Control unit, full set of cables

- High speed, long life spindle with quick stop brake and load control

- Manual, semi automatic tool change, 99 out of 99 tools per job

- Integral depth limiter and pressure foot

- Windows driver software RoutePro 2005 for drilling and routing

- Powerful 500-1500 Watt (adjustable) vacuum cleaner, remote controlled

|

| |

Special Features |

- Mechanics unit: rigid and flat construction with low moving weights and high quality bearings for high-speed positioning

- Machine bed with universal fixture system, suitable for clamp or span fixing or for reference pins (fiducials)

- KaVo high precision spindle motor, 150 Watt, 60 000 rpm, with heavy-duty long-life bearings, including 1/8" (3.2 mm) chuck

- Software controlled spindle speed. Electronic spindle load control with software feedback

- Spindle quick stop (1s) DC brake and speed-up booster

- Heavy duty 2x2 phase high-torque stepper motors on all 3 axes for true milling capability and correct tool speed

- All X/Y and Z traverse speed, working speed, working depth, spindle rpm and depth iterations individually configured on a per-tool basis, resulting in:

- Always adequate cutting speed over the entire spindle RPM range, no need for 100 K rpm spindles, no excessive wear to costly spindle bearings

- Standard travel area: 270 x 325 x 37 mm (larger machines available)

- Quick manual tool change by turning a knob, with machine position locked, no recalibration of height required

- Smallest tool diameter: 0.1 mm (micro end mill at 60 000 rpm)

- Max. hole diameter: infinite

- Integral depth limiting device for isolation milling and engraving on uneven surfaces, work level setting by Z stepper motor, depth fine adjustment with micrometer screw

- Removable, spring-load pressure foot for drillng of flexible and uneven PCBs

- Stack processing of several boards at once (typical stack: three 1.6 mm thick boards plus one underlay/base sheet)

- Working depth not limited by depth sensor, only by tool flute length (standard: 5..10 mm)

- Uses all common PCB drills/mills with 1/8" shank, with industry-standard length setting by collar

- Board fixture by "fiducials" possible at no extra cost, using standard base sheet material

- Possibility of mounting boards to machine zero point. Clamp fixing devices included with machine, span fixing for heavy-duty milling is possible

- Vacuum board fixation not recommended due to problems with board penetration by drilling

- Stand alone control unit connects to all standard PCs with 1 free USB or serial port

- Fully integrated Windows (98..XP) driver software for Excellon, Sieb&Meyer or HP/GL data for real-time, on-line machine control, with comfortable user interface, including full tool management and plausability control

- All machine parameters (speeds, acceleration ramps, X/Y/Z dimensions, scaling) software controlled and configurable

- Easy to use teach-in feature for drill data

- Step definition: Software selectable: 1 mil, 1/2 mil, 1/4 mil (= 6.35 micrometer)

- Resolution: 0.1 mil (= 2.54 micrometer)

- Precision +/- 1 step

- Positioning accurracy over entire workspace: 20 ppm (0.002%)

- Maximum traverse speed per axis: 130 mm/s

- Maximum working speed per axis: 130 mm/s, individual setting on a per-tool basis, independent from traverse speed

- Drill speed: 5 hits/s (=18000 holes per hour)

|

|

| |

| Technical Data |

- Power supply: 110-240 V, 50-60 Hz + vacuum cleaner (1500W)

- Sizes (mechanics): 70 x 55 cm

- Required desktop size: approx. 80 x 80 cm

- Weight: approx. 32 kg

|

| Computer not included |

| |

| Available Options |

| Protective hood, CAM / isolation software, monitor + camera, cooling device, compressor, etc. |

|

noise / dust protection-rack

available for

CCD-atc

CCD-mtc

CCD-2

|

|

|

|